When planning to invest in a laser marking machine in India, one of the first things buyers consider is the price. However, the cost of these machines can vary widely depending on several important factors. From the type of laser technology used to the machine’s features, brand reputation, and after-sales service, each element plays a role in determining the final price tag. Understanding these factors not only helps you make a more informed decision but also ensures you get the right balance of quality and value. In this blog, we’ll break down the 9 key factors that affect the laser marking machine price in India, giving you clarity before making your investment.

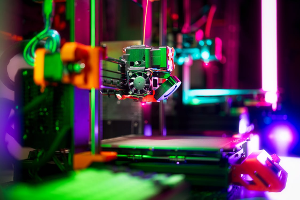

A major factor that affects the laser marking machine price in India is the type of laser technology used in the system. Different technologies, such as fiber lasers, CO₂ lasers, and UV lasers, come with varying capabilities and costs.

For example, machines with advanced UV laser technology are generally priced higher due to their precision and ability to mark delicate materials, while fiber lasers are often preferred for durability and speed in industrial applications. The choice of technology directly influences both the performance of the machine and its price, making it one of the most significant considerations for buyers.

Another important factor that affects the laser marking machine price in India is the power capacity of the machine. Higher power capacity machines are typically more expensive because they can handle tougher materials, deeper engravings, and faster marking speeds. Lower power machines, while more affordable, are generally suitable for lighter tasks or smaller-scale applications.

The required power depends on the type of material being marked and the level of precision or depth needed. As a result, the power capacity directly impacts both the machine’s capabilities and its overall price in the market.

A key factor that influences the laser marking machine price in India is the quality of components and build. Machines built with premium-grade parts, durable materials, and advanced engineering tend to cost more but offer greater reliability and longevity. High-quality components ensure stable performance, minimal downtime, and consistent marking accuracy over extended use.

On the other hand, machines made with lower-grade materials may come at a cheaper price but often compromise on durability and efficiency. Therefore, the overall build quality plays a significant role in determining the price as well as the long-term value of the machine.

Another factor that significantly affects the laser marking machine price in India is the brand reputation and reliability. Well-established brands often price their machines higher because they are trusted for consistent performance, durability, and dependable service.

A reputable brand usually invests in advanced technology, strict quality checks, and strong customer support, which add to the overall value. In contrast, lesser-known brands may offer lower prices but might not provide the same level of reliability or long-term assurance.

A major factor influencing the laser marking machine price in India is the features and customization options offered by the supplier. Machines equipped with advanced features such as automated positioning, adjustable marking speed, or multi-material compatibility generally come at a higher price.

Similarly, customization options that allow the machine to be tailored to specific industry needs add to the overall cost. While these features increase the upfront price, they also enhance efficiency, precision, and flexibility, making the machine more valuable for specialized applications.

An important factor that affects the laser marking machine price in India is software compatibility and upgrades. Machines that come with advanced, user-friendly software capable of supporting various design formats and complex operations often cost more.

Additionally, the ability to receive regular software updates ensures that the machine stays compatible with evolving technologies and user requirements. Such compatibility not only improves ease of operation but also extends the long-term value of the investment.

Another factor that plays a vital role in determining the laser marking machine price in India is the after-sales service and support provided by the supplier. Machines backed by strong service networks, quick response times, and reliable technical assistance usually come with a higher price tag.

This is because comprehensive support ensures smooth operation, minimal downtime, and prompt solutions to any issues that may arise. Buyers often pay more for the assurance of dependable service, knowing it adds long-term value and peace of mind.

A significant factor that affects the laser marking machine price in India is the warranty and maintenance coverage offered by the supplier. Machines that come with extended warranties or inclusive maintenance plans are generally priced higher, as these provide added security and long-term reliability.

Such coverage ensures that any potential issues can be resolved without unexpected expenses, reducing operational risks for the buyer. On the other hand, a limited or no warranty may lower the upfront cost but could result in higher maintenance expenses later.

An important factor that influences the laser marking machine price in India is import duties and local taxes. Since many laser marking machines or their components are imported, the customs duties and tariffs applied to them can significantly raise the overall cost. Additionally, local taxes such as GST further add to the final price paid by the buyer.

These charges vary depending on government regulations and import policies, making them a key element in price fluctuations. As a result, import duties and local taxes directly impact how much a laser marking machine will cost in the Indian market.

The laser marking machine price in India is influenced by a range of factors that extend beyond the equipment's basic cost. Elements such as the type of laser technology, power capacity, and build quality directly influence performance and durability, while brand reputation, features, and software compatibility add further value. At the same time, after-sales service, warranty coverage, and even external aspects like import duties and local taxes play a crucial role in the final pricing. By understanding these nine factors, buyers can make informed decisions, balancing budget with long-term reliability and efficiency.