Types of Milling

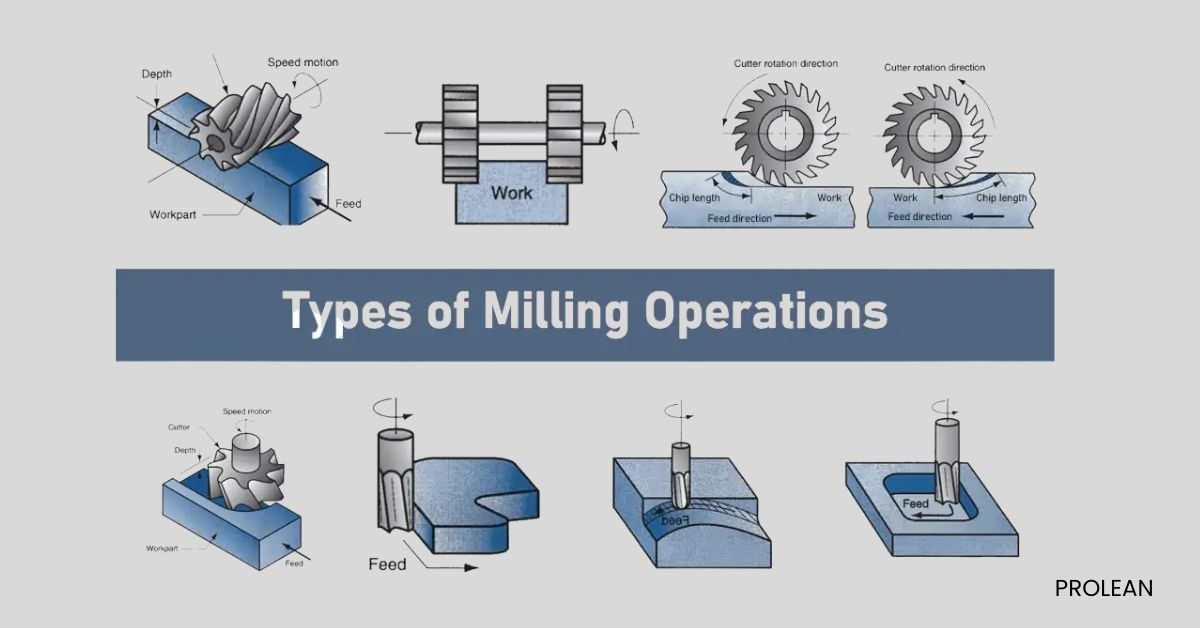

Milling is a fundamental manufacturing process that converts raw materials into skimmed parts. Using circular cutters, milling involves removing material while achieving the correct dimensions. Compared to shapers or lathes, milling is faster, can perform complex tasks, and is widely used by industries such as automotive and aerospace manufacturing.

There are many different types of milling that are designed for particular machining operations, which can include slotting and contouring. With automation becoming prevalent, there are now custom CNC milling services that make it possible to manufacture complex parts in mass with accuracy and efficiency.

This article will explore 15 different types of important milling operations, with a discussion of their uses and applications of each method of machining.

Milling machines are of various types, each designed to perform different types of milling processes. CNC milling processes involve advanced interaction of the computer-operated machines with the cutting material, such as metals.

Let’s discuss some common types of milling below.

End milling is the milling process in which end mills are used. End mills are cylindrical cutting tools whose ends are used to cut the workpiece. End milling is used to create the precise cuts for intricate geometrical shapes. It is also used in other milling operations like slot making, pockets, and contours.

Face milling is a metal cutting process that utilizes flat mills as cutting tools in a CNC machine. As the name suggests, these cutting mills have flat edges to cut the material. In this process, the cutting tool is placed perpendicular to the workpiece and hence used for surface milling to create smooth, flat surfaces. This technique is for wide area blocks.

Slot milling is a metal milling operation used to create the slots in the required metal. For this purpose, end mills and slot cutting mills are used. End mills can work on the ends as well as inside positions. However, slot mills can only be used to create blind holes, as they work on the inside positions.

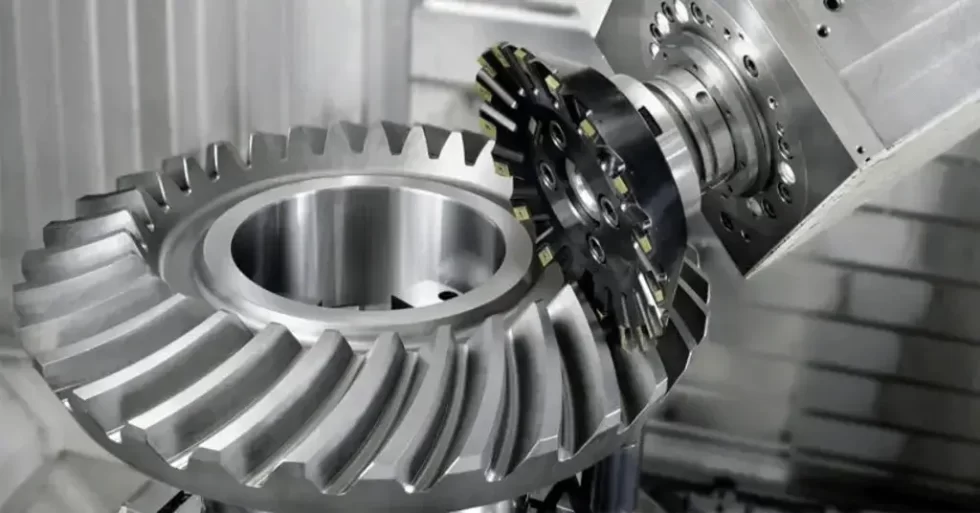

Gear Milling

Gear Milling

Gear milling is a specific type of milling machining in which gear milling or gear hobbing cutters are used to generate the gears or teeth of gears. This process holds great importance in the automotive industry.

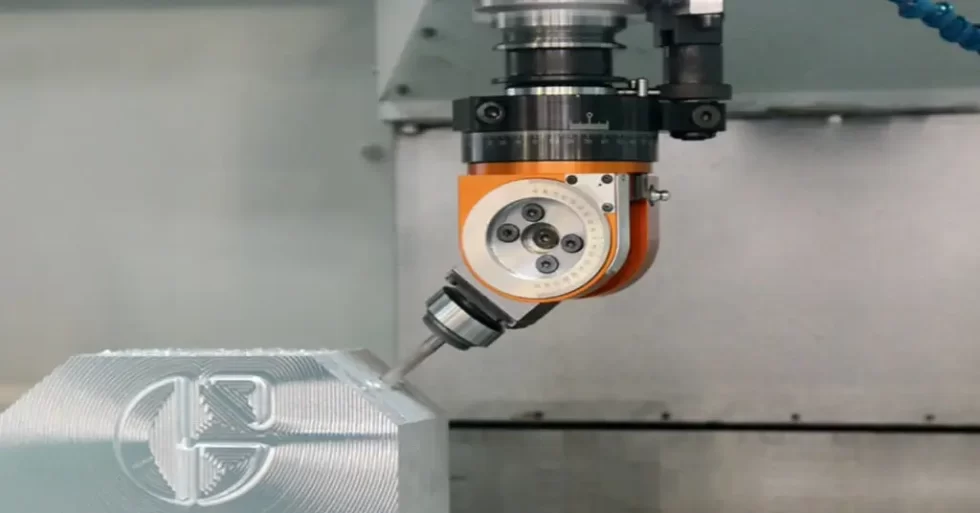

Profile milling process uses a ball-shaped cutting tool. It is a unique milling type that works to create multiple forms and edges on the particular workpiece. It uses several numbers of axes, and some milling operations require more axes, while some need fewer. Profile milling is popular for higher dimensional accuracy and precision.

The shoulder milling process uses a side cutter to remove the material from the sides or shoulder of the metal. It produces the right size of shoulders as per the given design. Vertical or horizontal milling machines are used with optimized control for accurate shoulders.

Sawmilling is a process used to transform the material into thin plates or thin parts. This milling machining is done with a large-diameter metal cutting tool that has several blades on its circumference. It looks like a cylindrical saw.

The gang milling process involves the simultaneous functioning of several milling tools. It also includes slab and end mills. This process is used to produce the parts that have to perform multiple functions at the same time. The presence of different cutting tools ensures the efficiency and performance of the end product.

Side milling uses the side cutter or end mill to work on the sides of the material. It produces different shapes like grooves, pockets, or slots.

Form milling is a special type of CNC milling machining. It involves the customized cutting tools having an exact match profile with the design to be created. The cutting edges of the tool create the cuts on the workpiece, and parts are produced in one continuous go. This process is used to machine the intricate, complex parts with high accuracy.

In straddle milling, two side cutters are used simultaneously for machining the workpiece. This is often used for the materials that have two flat surfaces and both need to be milled at the same time. It helps in creating parallel grooves and slots in the job material.

Angle Milling

Angle Milling

Angle milling process is used to create specific features on the workpiece at an angle with the tool axis. The unwanted material is removed from the metal by placing it in an angular position. It is usually used to create products that have cross-sectional profiles or features like slots, dovetail slots, and bevels.

CAM milling machining is used to create the CAM parts. These are the parts that convert motion into mechanical systems. CAM milling involves the use of head cutting tools that work on the material to give it the right shape.

Thread Milling

Thread Milling

In the thread milling, the sharp-edged cutting tool is employed to create threads. This process is also used to produce taps or dies, but it is popular for finished and high-performance threads needed in different components.

Step milling is a milling technique that is used to create shallow cuts with a high feed rate and less required time.

Milling is an important machining process that supports industries by making accurate, efficient parts. The types of milling discussed above demonstrate just how versatile the milling process can be, with applications ranging from basic slots to complex profiles. Every type of milling has a specific purpose, and all strive towards precision, speed, and reliability in production.

With the advancement of automation and custom CNC milling, companies can now achieve higher levels of efficiency while providing custom designs to varying levels of complexity. Selecting the proper milling operation is based on the application at hand, but all milling operations are used to create usable, high-quality parts from raw materials in various applications in the modern world.