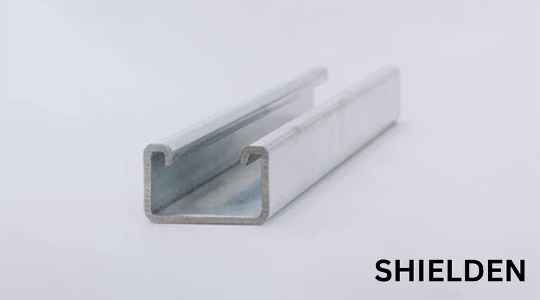

For contractors working in electrical construction, HVAC installation, industrial piping, and solar mounting, strut channels are essential components that keep structures safe, stable, and efficient. But as material prices rise and project timelines grow tighter, reducing unnecessary expenses has become a top priority. This is where choosing the right partner among global strut channel manufacturers can make a significant difference. Increasingly, contractors are turning to Shielden not only for dependable quality but also for its ability to tailor strut channels to exact project requirements—leading to substantial cost savings.

Shielden’s custom manufacturing capabilities have become a strategic advantage for contractors who want precision-engineered solutions without budget overruns. While many strut channel manufacturers simply offer standard catalog items, Shielden takes a more adaptable approach, focusing on how customization can eliminate waste, shorten installation time, and optimize material performance.

Reducing Material Waste Through Precision Sizing

One of the biggest hidden expenses on construction sites comes from cutting and adjusting strut channels during installation. Standard lengths do not always match real-world measurements, resulting in leftover pieces that cannot be reused. Shielden minimizes these losses by offering custom lengths and dimensions tailored to each project’s layout.

Contractors benefit from:

By receiving channels that fit perfectly from the start, contractors save both labor hours and material costs. This level of customization is one of the reasons Shielden stands out among competing strut channel manufacturers.

Customized Materials That Match Project Environments

Not all construction environments demand the same type of metal. Coastal projects require high corrosion resistance, while indoor mechanical rooms may only need standard galvanized steel. Shielden provides a wide selection of materials—such as 304/316 stainless steel, aluminum alloy, Z275 steel, and G90 steel—and helps contractors choose the most cost-effective option without compromising safety.

Choosing the correct material from the beginning prevents:

Shielden’s material guidance ensures contractors do not overpay for features they do not need, while still protecting long-term performance.

Labor Savings Through Ready-to-Install Design

Labor often accounts for the largest portion of a contractor’s budget. With this in mind, Shielden designs its strut channels and accessories for easy and fast assembly. Instead of spending valuable time adjusting incompatible parts, contractors receive components that fit together flawlessly.

Shielden’s custom capabilities include:

Compared to many traditional strut channel manufacturers, Shielden places a greater emphasis on installation efficiency, helping contractors complete jobs faster and with fewer workers.

Improved Structural Performance Means Fewer Repairs

A poorly matched strut channel system can lead to problems within months—especially in environments with vibration, moisture, or constant mechanical load. Shielden’s customization process considers load calculations, environmental conditions, and application requirements to ensure optimal strength and stability.

Stronger systems result in:

Contractors appreciate how Shielden balances durability with cost efficiency, delivering long-term value rather than short-term savings.

Bulk Production Tailored to Contractor Workflows

Many contractors work on multiple simultaneous projects and require consistent deliveries to avoid delays. Shielden supports these needs with bulk manufacturing tailored to specific schedules and specifications. This predictability reduces downtime and eliminates the need to source last-minute materials at higher prices.

Shielden also offers:

This full-service approach makes Shielden a dependable partner when compared with other strut channel manufacturers that only provide limited production capability.

Cost-Effective Finishes That Extend Product Lifespan

Choosing the right finish is essential for preventing rust and maintaining structural strength. Shielden offers hot-dip galvanized, powder-coated, black finish, electro-galvanized, and pre-galvanized coatings—all available for customization depending on the budget and environment.

Customizing the finish helps contractors avoid:

This fine-tuned approach allows contractors to balance cost and durability with precision.

Streamlined Accessory Compatibility Saves Time and Money

A significant challenge many contractors face is compatibility between channels and accessories. Mismatched components often cause delays or unsafe assemblies. Shielden eliminates this issue by producing a full range of accessory options designed to integrate smoothly with its strut channels.

Contractors benefit through:

Choosing a unified system from Shielden prevents the hidden costs that often arise when sourcing parts from multiple strut channel manufacturers.

Conclusion

In the construction and engineering world, cost control is no longer just about choosing the cheapest materials—it’s about partnering with a manufacturer that understands how customization can maximize efficiency, minimize waste, and improve long-term performance. Shielden has positioned itself as a leader among global strut channel manufacturers by offering tailored solutions that directly address these goals.

Through precise sizing, material customization, improved installation readiness, and a complete ecosystem of compatible accessories, Shielden enables contractors to lower expenses without sacrificing quality. As demand grows for smarter, more adaptable infrastructure solutions, Shielden’s custom strut channel manufacturing continues to provide a practical and cost-saving advantage for contractors worldwide.